The construction of a solar cell is a fascinating process that involves meticulous planning, precise execution, and the integration of various components. In this article, I will take you through the step-by-step journey of how a solar cell goes from a blueprint to a fully functional energy-generating marvel.

The construction begins with the creation of a detailed blueprint or design that outlines the specifications, dimensions, and materials needed for the solar cell. This blueprint serves as a guide throughout the construction process, ensuring accuracy and efficiency.

Once the blueprint is ready, the next crucial step is gathering the necessary materials. High-quality semiconductor materials, such as silicon, are sourced and prepared meticulously to ensure optimal performance. Metal contacts, which facilitate the flow of electricity, are also prepared and integrated into the construction process.

The assembly and integration phase is where the solar cell truly comes to life. Thin layers of semiconductor material are deposited onto a substrate, forming the active area of the cell. Metal contacts are strategically placed to enable efficient electron flow, while antireflective coatings ensure maximum light absorption. These components are carefully arranged and interconnected to create a functional and efficient solar cell.

The construction of a solar cell is a meticulous process that demands expertise and attention to detail. Each step, from blueprint creation to material preparation and assembly, contributes to the overall performance and longevity of the solar cell. By understanding and optimizing the construction process, we can continue to advance solar cell technology and harness the power of the sun for a sustainable future.

Key Takeaways:

- The construction of a solar cell involves several key steps, starting with the creation of a blueprint or design.

- Gathering and preparing high-quality materials, such as silicon and metal contacts, is crucial for the construction process.

- The assembly and integration phase brings together various components to form a functional solar cell.

- Precise techniques and attention to detail are essential in ensuring the performance and longevity of solar cells.

- Optimizing the construction process is vital for advancing solar cell technology and promoting sustainability.

Gathering and Preparing the Materials

In order to construct a solar cell, the first crucial step is to gather and prepare the necessary materials. This involves sourcing high-quality solar cell materials, such as silicon, which serves as the primary semiconductor material utilized in most solar cells.

The next step is to process and purify the silicon to remove any impurities and create the desired electrical properties. This purification process ensures that the silicon exhibits optimal efficiency and performance in converting sunlight into electricity.

In addition to silicon, another essential component in solar cell construction is metal contacts. These metal contacts are responsible for facilitating the flow of electricity within the solar cell. They are carefully prepared and positioned to ensure optimal electrical connections and efficient energy transfer.

By sourcing high-quality silicon and preparing precise metal contacts, the solar cell is equipped with the necessary materials to effectively harvest and convert sunlight into usable electrical energy.

When it comes to the construction of solar cells, the quality of the materials used plays a significant role in determining the efficiency and longevity of the final product. By gathering and preparing the right materials, including high-quality silicon and well-designed metal contacts, solar cell manufacturers can ensure the optimal performance and durability of their products.

Next, let’s explore the assembly and integration process involved in constructing a solar cell.

Assembly and Integration

Once the materials are prepared, they are assembled and integrated to create the solar cell. This crucial step in the construction process involves several sub-steps that ensure the successful integration of each component.

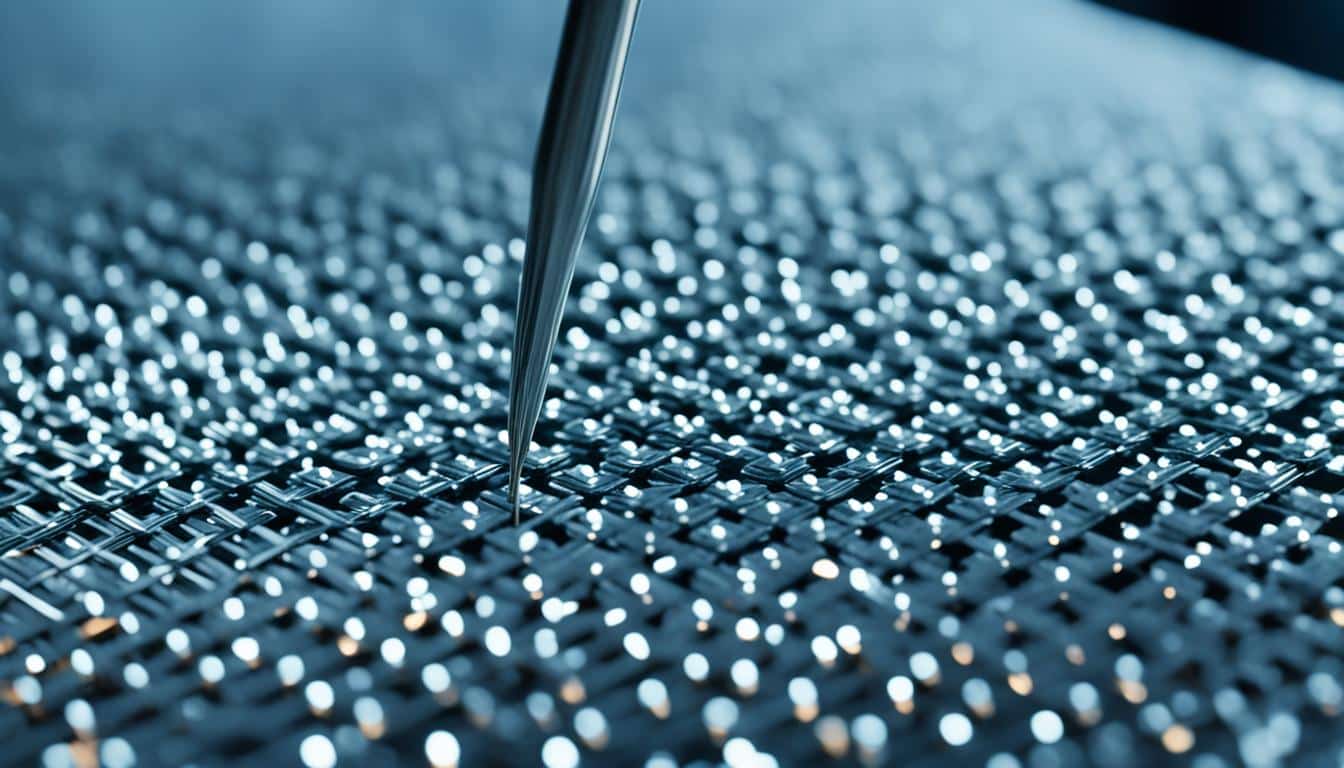

Deposition of Semiconductor Material

One of the key sub-steps during assembly is the deposition of thin layers of semiconductor material onto a substrate. This process, known as thin-film deposition, plays a pivotal role in the performance and efficiency of the solar cell. The semiconductor material, typically silicon, is carefully applied onto the substrate using specialized techniques such as chemical vapor deposition or physical vapor deposition.

Placement of Metal Contacts

In addition to the deposition of semiconductor material, the placement of metal contacts is also a critical part of the assembly process. Metal contacts play a vital role in facilitating the flow of electricity within the solar cell. These contacts are strategically positioned to establish electrical connections between the semiconductor layers and external circuitry, ensuring efficient energy transfer.

Creation of Antireflective Coatings

To optimize the absorption of sunlight and enhance the overall performance of the solar cell, antireflective coatings are applied. These coatings minimize the loss of incoming light due to reflection, allowing the solar cell to capture a greater amount of sunlight. The antireflective coatings are carefully designed and applied to reduce surface reflections and maximize the efficiency of the solar cell.

The assembly process requires meticulous attention to detail and precision to ensure the integrity and performance of the final product. Each component, from the thin layers of semiconductor material to the strategically placed metal contacts and antireflective coatings, must be precisely arranged and interconnected to form a functional solar cell.

Through the careful assembly and integration of these components, the solar cell becomes capable of converting sunlight into usable electrical energy. The successful combination of materials and precise techniques during the assembly process ultimately determines the effectiveness and efficiency of the solar cell.

Conclusion

In conclusion, the construction of a solar cell is a meticulous process that requires expertise and attention to detail. Each step, from the gathering of materials to the assembly and integration of components, plays a crucial role in the overall performance and efficiency of the solar cell.

The construction process is guided by blueprints or designs, taking into account the dimensions, materials, and components required for optimal functionality. High-quality materials, such as silicon for the primary semiconductor, and specially prepared metal contacts, are essential for achieving the desired electrical properties and facilitating the flow of electricity within the solar cell.

The importance of proper construction cannot be overstated. A well-constructed solar cell directly impacts energy conversion efficiency and longevity. By understanding and optimizing the construction process, we can continue to advance solar cell technology and harness the power of the sun for a sustainable future.

FAQ

What is the first step in the construction of a solar cell?

The first step involves creating a blueprint or design for the solar cell, outlining its dimensions, materials, and components.

What materials are used in the construction of a solar cell?

The construction of a solar cell requires semiconductor materials like silicon and conductive materials such as metal contacts.

How are the materials prepared for the assembly of a solar cell?

The materials, including silicon and metal contacts, are processed and purified to remove impurities and create the desired electrical properties.

What is involved in the assembly and integration of a solar cell?

The assembly process includes depositing thin layers of semiconductor material onto a substrate, placing metal contacts, and creating antireflective coatings.

Why is proper construction important for a solar cell?

Proper construction ensures the performance, efficiency, and longevity of the solar cell, directly impacting its energy conversion efficiency.